Vision

The Vision of the aiCAMstir project was determined during a friction stir welding training course in Munich.

Summary

Some years ago, Stephan Kallee had worked on a project on making tailor welded blanks by friction stir welding. A new spindle, a new jig, two FSW experts and a new technician were available, who was experienced in operating milling machines but had not received in-depth training on parameter optimisation. Due to an unforeseen business trip, they worked on three different sites: in the lab, in the office and in a hotel. They could only communicate by mobile phone, sharing photos and information on the parameter settings. After a few iterations, optimised parameters could be found.

A few years later, he considered using neuro-networks for optimising FSW parameters. During a training course in Munich, the concept of using artificial intelligence in computer aided manufacturing was discussed in more detail and a project with very promising results was conducted.

In the aiCAMstir project we want to go one step further. We want to create a cloud, into which FSW operators can upload images and information on parameter settings during feasibility studies, prototyping, production ramp-up and series production, and get feedback about the weld quality and recommendations on optimising the parameters. In the final stage, such a system would be integrated into the FSW machine, and the machine would optimise the parameters itself within boundaries set by the operator.

The vision was explained for the first time in public during an on-line discussion with students of the University of Liège on 19 April 2021.

The first welds

The first welds were made by a group of experts and trainees in Munich. The trainees could choose the parameters after discussions with the experts and found visually acceptable parameter settings after a few iterations. The parameter matrix investigated during the course is shown below:

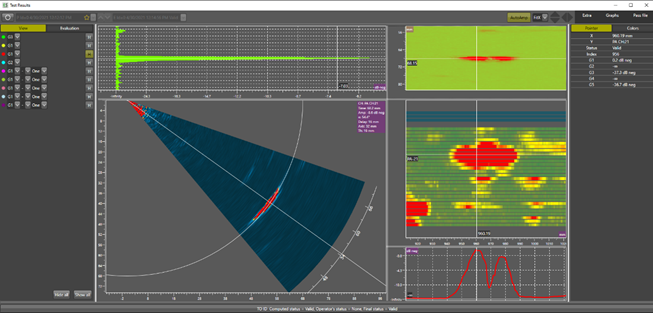

The next step: Automated PAUT-TOFD

The aiCAMstir concept might also be useful for PAUT-TOFD examination with the Sonaflex system. The Sonaflex system makes use of an industrially proven, automatic ultrasonic inspection system combining Phased Array Ultrasonic Testing (PAUT) and Time of Flight Diffraction (TOFD) developed by Nordinkraft AG. The aiCAMstir software could be modified to evaluate screenshots of the NDT data in the same way as processing optical photographs for automated quality control during friction stir welding. Please contact stephan.kallee@alustir.com to discuss this in more detail.