Main Page: Difference between revisions

Jump to navigation

Jump to search

No edit summary |

No edit summary |

||

| Line 10: | Line 10: | ||

|+ Caption text | |+ Caption text | ||

|- | |- | ||

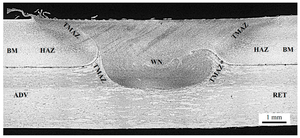

| [[File: | | [[File:Conventinal butt welding tool used for lap joints at 1200 rpm at 250 mm per min, © Egoitz Aldanondo, Javier Vivas, Pedro Álvarez (LORTEK) and Iñaki Hurtado (MU-ENG), CC BY 4.0.webp|thumb|centre|Benchmark: Conventinal butt welding tool used for lap joints at 1200 rpm at 250 mm/min<ref>Egoitz Aldanondo, Javier Vivas, Pedro Álvarez (LORTEK) and Iñaki Hurtado (MU-ENG): [https://www.mdpi.com/2075-4701/10/7/872 ''Effect of Tool Geometry and Welding Parameters on Friction Stir Welded Lap Joint Formation with AA2099-T83 and AA2060-T8E30 Aluminium Alloys.''] Metals 2020, 10(7), 872, [http://creativecommons.org/licenses/by/4.0/ CC BY 4.0].</ref>]] || [[File:Zeichen 123 - Baustelle, StVO 1992.svg|thumb|centre|Currently under construction]] | ||

|- | |- | ||

| Example || Example | | Example || Example | ||

Revision as of 21:25, 8 April 2021

aiCAMstir: Artificial Intelligence based Computer Aided Manufacturing of Friction Stir Welds

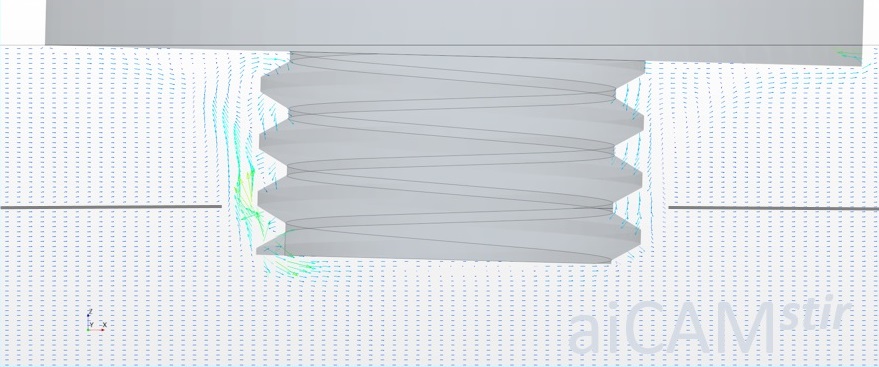

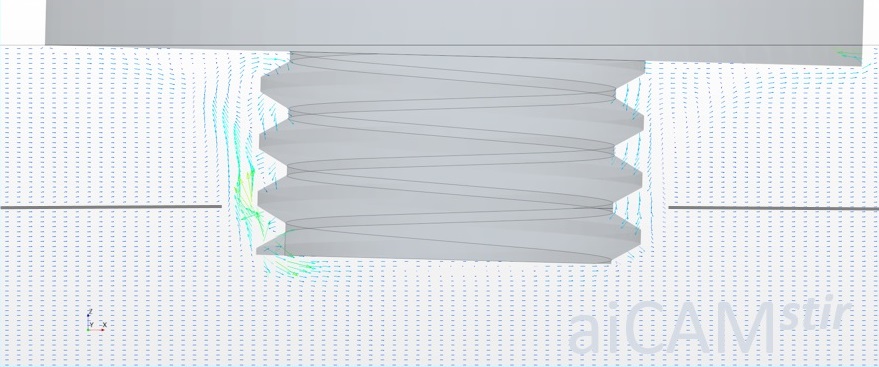

Computional Fluid Dynamics will be used for optimising the tool design of aiCAMstir tools for lap welding[1]

It is difficult to choose and optimise the friction stir welding tool design and welding parameters for lap welding, as shown by many publications.[2]

Thus, the objective is to add a new aiCAMstir computer aided manufacturing control system to FSW machines, which recommends (or even automatically optimises) parameters based on computational fluid dynamics (CFD), finite element analysis (FEA), design of experiments (DOE), Wikipedia-like open source cloud data and artificial intelligence (AI) including machine learning.

Benchmark: Conventinal butt welding tool used for lap joints at 1200 rpm at 250 mm/min[3] |

|

| Example | Example |

| Example | Example |

| Example | Example | Example |

| Example | Example | Example |

Test[4]

See also

References

- ↑ Mike Lewis and Simon D. Smith: The Development of FSW Process Modelling for Use by Process Engineers. In: The Minerals, Metals & Materials Society 2021: Friction Stir Welding and Processing XI. 17 Feb 2021.

- ↑ Matthew Champagne (University of New Orleans): Investigation of 2195 and 2219 Post Weld Heat Treatments for Additive Friction Stir Lap Welds. Pages 9, 20-21.

- ↑ Egoitz Aldanondo, Javier Vivas, Pedro Álvarez (LORTEK) and Iñaki Hurtado (MU-ENG): Effect of Tool Geometry and Welding Parameters on Friction Stir Welded Lap Joint Formation with AA2099-T83 and AA2060-T8E30 Aluminium Alloys. Metals 2020, 10(7), 872, CC BY 4.0.

- ↑ Reference