Data to be processed: Difference between revisions

Jump to navigation

Jump to search

No edit summary |

|||

| Line 81: | Line 81: | ||

* Use ''Data Mining'' to process the data according to specific needs | * Use ''Data Mining'' to process the data according to specific needs | ||

** Advantages: Infrastructure will be installed. Data transfer is standardised | ** Advantages: Infrastructure will be installed. Data transfer is standardised | ||

** | ** Disadvantages: There might be no short-term benefit. Creation and storage of data garbage<sup>[https://en.wikipedia.org/wiki/Garbage_(computer_science) (WP)]</sup> | ||

=== Top Down === | === Top Down === | ||

* | * Specific objectives | ||

* | * Data collection is related to the needs | ||

** Advantage: | ** Advantage: Very good cost-benefit-ratio. Simple entry and fast progress | ||

** | ** Disadvantages: Risk of insular solutions. Data might not be sufficient for the next project | ||

== References == | == References == | ||

<references /> | <references /> | ||

Revision as of 08:02, 30 April 2021

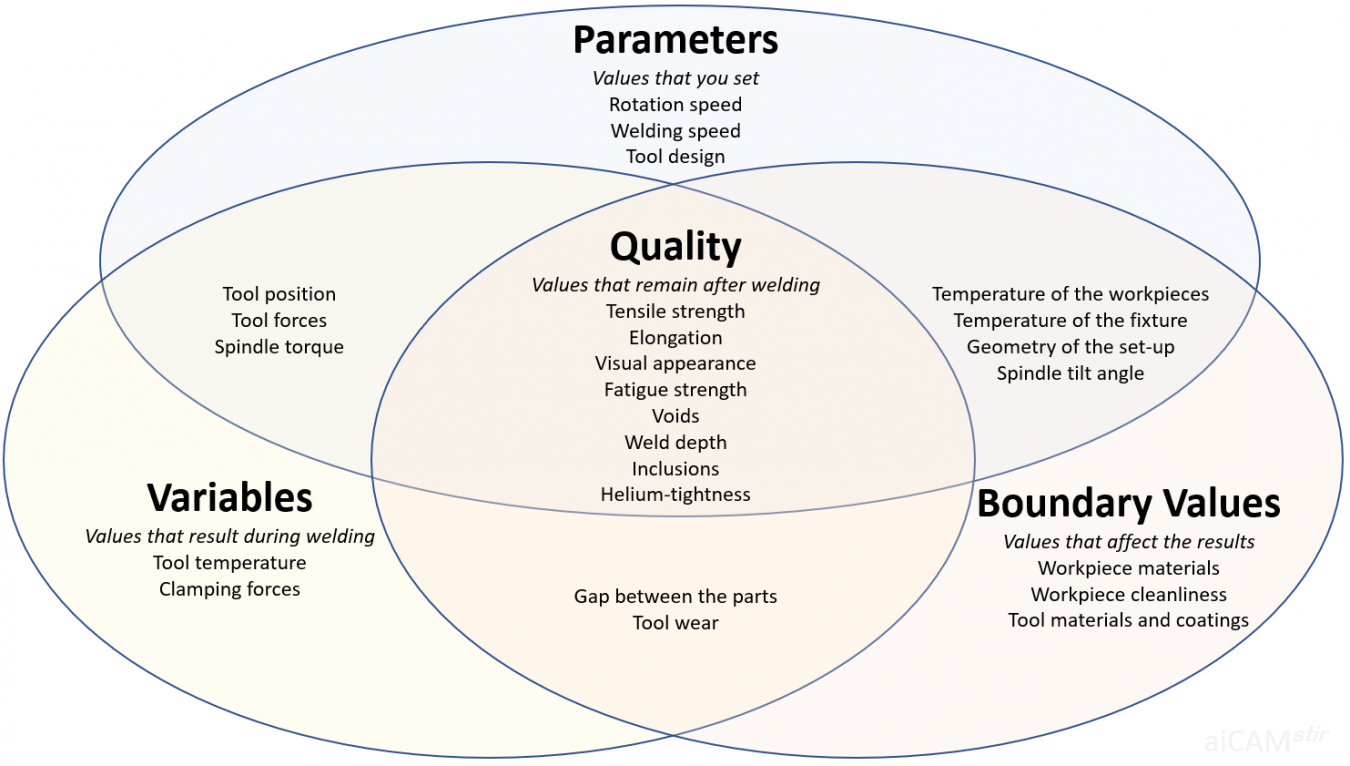

Data to be processed in the aiCAMstir project are parameters, variables, boundary values and quality.

Key data to be processed

According to digitalisation and data processing experts, the following categorisation of key data could be considered:

| Parameters | Variables | Boundry Values | Quality |

|---|---|---|---|

| Values that you set | Values that result during welding | Values that affect the results | Quality |

|

|

|

|

|

|||

|

|||

The categorisation depends on the concept and complexity of the machine. Modern FSW machines provide close-loop force and position control algorithms, which complicate the distinction between parameters and variables. Some machines use the temperature as a parameter that can be set, e.g. to change the parameters if the tool gets too hot.

Please feel free to improve the classification above or to propose an alternative classification. Or use the discussion page for discussing changes.

CAM and FSW

- Computer Aided Manufacturing (CAM) includes data monitoring, data processing and data visualisation

- Friction Stir Welding (FSW) is a special process, and its quality can only be determined statistically

Benefits

- Simplify the data exchange

- Reduce the reaction time

- Automate the documentation

- Provide more attractive products and services[1]

Traps

- CAM has no value by itself

- Humans need to be involved

- Raw data aren't providing information

- Visual management is required[1]

The two approaches to data collection and processing

Bottom Up

- Collect and store as much data as possible at all times

- Use Data Mining to process the data according to specific needs

- Advantages: Infrastructure will be installed. Data transfer is standardised

- Disadvantages: There might be no short-term benefit. Creation and storage of data garbage(WP)

Top Down

- Specific objectives

- Data collection is related to the needs

- Advantage: Very good cost-benefit-ratio. Simple entry and fast progress

- Disadvantages: Risk of insular solutions. Data might not be sufficient for the next project

References

- ↑ 1.0 1.1 Marion Purrio and Guido Buchholz (FEF Forschungs- und Entwicklungsgesellschaft Fügetechnik GmbH)Webinar: Vorgehensweise bei Digitalisierungsprojekten in der Schweißtechnik. 29 April 2021.