Data to be processed: Difference between revisions

Jump to navigation

Jump to search

No edit summary |

No edit summary |

||

| Line 23: | Line 23: | ||

|| | || | ||

*Tool position | *Tool position | ||

*Tool temperature | *Tool temperature | ||

*Clamping forces | *Clamping forces | ||

|| | || | ||

*Tool design | *Tool design | ||

*Tool | *Tool materials and coatings | ||

*Workpiece materials | *Workpiece materials | ||

*Room temperature | *Room temperature | ||

| Line 47: | Line 42: | ||

*Inclusions | *Inclusions | ||

*Helium-tightness | *Helium-tightness | ||

|- | |||

|colspan="2"| | |||

*Tool forces | |||

*Tool torque | |||

|colspan="2"| | |||

*Gap between the parts | |||

*Tool wear | |||

|- | |||

|- | |||

|| | |||

|colspan="2"| | |||

*Temperature of the workpieces | |||

*Temperature of the fixture | |||

*Geometry of the set-up | |||

|| | |||

|- | |||

|} | |} | ||

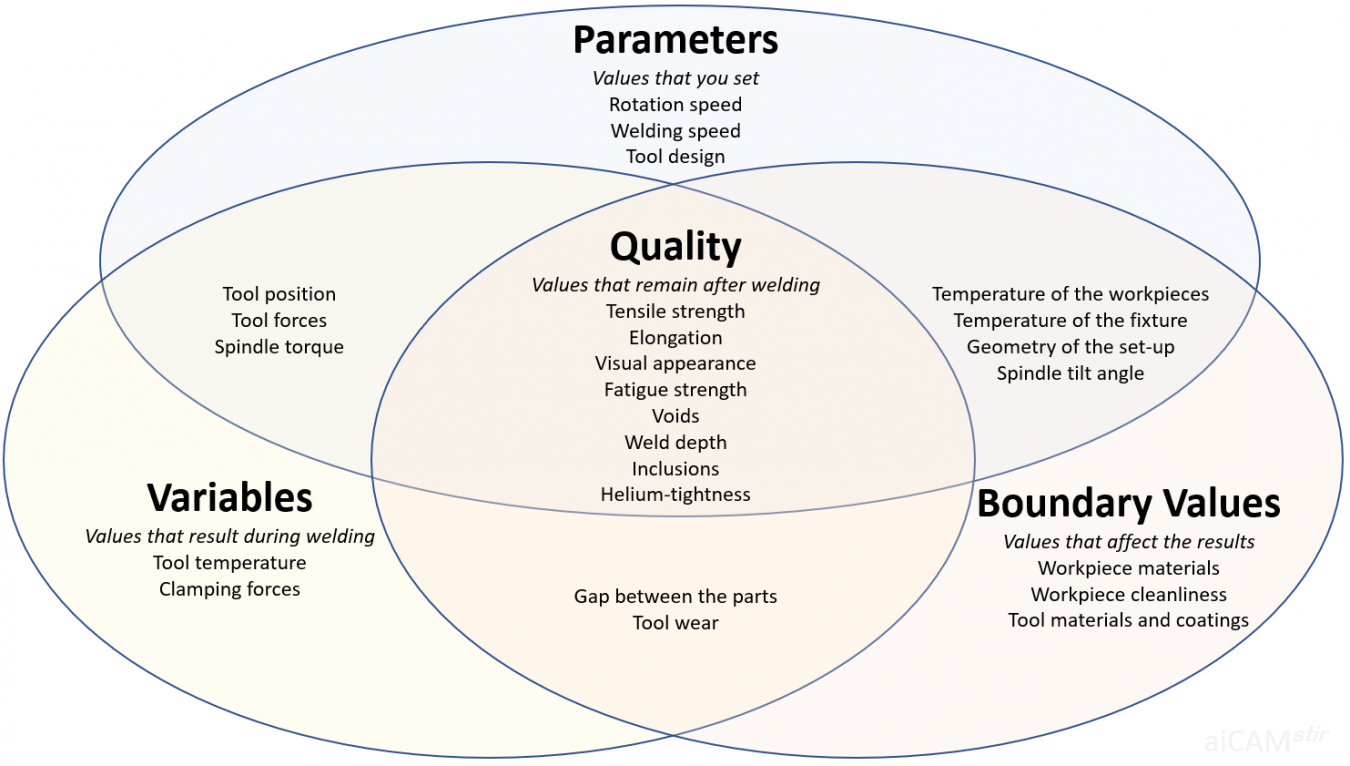

The categorisation depends on the concept and complexity of the machine. Modern FSW machines provide close-loop force and position control algorithms, which complicate the distinction between parameters and variables. Some machines use the temperature as a parameter that can be set, e.g. to change the parameters if the tool gets too hot. | The categorisation depends on the concept and complexity of the machine. Modern FSW machines provide close-loop force and position control algorithms, which complicate the distinction between parameters and variables. Some machines use the temperature as a parameter that can be set, e.g. to change the parameters if the tool gets too hot. | ||

Please feel free to improve the classification above or to propose an alternative classification. | Please feel free to improve the classification above or to propose an alternative classification. | ||

Revision as of 15:26, 29 April 2021

Data to be processed in the aiCAMstir project are parameters, variables, boundary values and quality.

According to digitalisation and data processing experts, the following categorisation of key data could be considered:

| Parameters | Variables | Boundry Values | Quality |

|---|---|---|---|

| Values that you set | Values that result during welding | Values that affect the results | Quality |

|

|

|

|

|

| ||

|

|||

The categorisation depends on the concept and complexity of the machine. Modern FSW machines provide close-loop force and position control algorithms, which complicate the distinction between parameters and variables. Some machines use the temperature as a parameter that can be set, e.g. to change the parameters if the tool gets too hot.

Please feel free to improve the classification above or to propose an alternative classification.