File:Surface of High Rotation Speed Friction Stir Welding Joint of a 6061-T6 (b) flash and groove (S1, 200 mm per min). Yang Zhou et al, Metals 2018, 8(12), 987, CC BY 4.0.png

Original file (1,198 × 824 pixels, file size: 622 KB, MIME type: image/png)

This file is from Wikimedia Commons and may be used by other projects. The description on its file description page there is shown below.

Contents

Summary

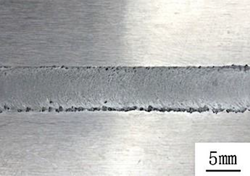

| DescriptionSurface of High Rotation Speed Friction Stir Welding Joint of a 6061-T6 (b) flash and groove (S1, 200 mm per min). Yang Zhou et al, Metals 2018, 8(12), 987, CC BY 4.0.png |

English: High Rotation Speed Friction Stir Welding Joint of a 6061-T6 Aluminum Alloy Sheet |

| Date | Received: 30 October 2018; Accepted: 21 November 2018; Published: 24 November 2018; Uploaded onto Wikimedia Commons: 26 October 2022 |

| Source | Yang Zhou, Shujin Chen, Jiayou Wang, Penghao Wang and Jingyu Xia: Influences of Pin Shape on a High Rotation Speed Friction Stir Welding Joint of a 6061-T6 Aluminum Alloy Sheet. Metals 2018, 8(12), 987; DOI:10.3390/met8120987. CC BY 4.0. |

| Author | Yang Zhou, Shujin Chen, Jiayou Wang, Penghao Wang and Jingyu Xia |

Abstract

1 mm thick 6061-T6

Yang Zhou and his colleagues chose three kinds of pins, to perform high rotation speed friction stir welding on a 1 mm thick 6061-T6 aluminium alloy in order to explore the influences of different pins on the weld based on the specialty of the aluminium alloy sheet welding. The microstructure and mechanical properties of the joints were analysed at the same time. When the rotation speed was 11,000 rpm and the welding speed was 300 mm/min, more sufficient stirring and a better joint (the tensile strength reaches 87.2% of the base metal) can be obtained with the pin design of a quadrangular frustum pyramid. The pattern of the weld cross section was a “flat T” and no obvious “S curve” was found in nugget zone (NZ). Heat affected zone (HAZ) and thermo-mechanically affected zone (TMAZ) were also narrow. The results demonstrate that the proportion of low angle boundaries in each area of the weld is lower than that of traditional Friction Stir Welding (FSW). The grain size of NZ is significantly refined and the proportion of low angle boundaries is only 20.1%, which have improved the welding quality.[1]

Conclusions

They selected three kinds of pins to perform high rotation speed FSW on a 1 mm 6061-T6 aluminum alloy sheet. Their conclusions were as follows:

- When the shape of the pin is a quadrangular frustum pyramid, the rotation speed is 11,000 rpm and the travel speed is 300 mm/min, and soundable joints are obtained.

- Due to the stirring effect of high rotation speed, the proportion of low angle boundaries in all zones is lower than that of the traditional FSW, while the average grain size is similar to traditional FSW.

- The proportion of low angle boundaries in HAZ, TMAZ, and NZ is 50%, 23.3%, and 20.1%, respectively.

- The tensile strength of specimen W2 is 265 MPa, which accounts for 87.2% of the base metal.

- The pattern of the weld cross section is “flat T”.

- HAZ and TMAZ are narrow and no obvious “S curve” is found in the weld, which is different from the traditional FSW.

Similar photos

| Photo | Specimen No |

Welding Speed (mm/min) |

Rotation Speed (rpm) |

Tool Pin Shape | Comment | Ref. |

|---|---|---|---|---|---|---|

|

(a) | 300 or 400 | 11,000 | S2: quadrangular frustum pyramid | Smooth | [1] |

|

(b) | 200 | 11,000 | S1: quadrangular prism | Flash and groove | [1] |

|

(c) | 500 | 11,000 | S3: frustum | Groove | [1] |

|

(d) | 200 | 11,000 | S2: quadrangular frustum pyramid | Rough | [1] |

References

- ↑ a b c d e Yang Zhou, Shujin Chen, Jiayou Wang, Penghao Wang and Jingyu Xia: Influences of Pin Shape on a High Rotation Speed Friction Stir Welding Joint of a 6061-T6 Aluminum Alloy Sheet. Metals 2018, 8(12), 987; DOI:10.3390/met8120987. CC BY 4.0.

Licensing

- You are free:

- to share – to copy, distribute and transmit the work

- to remix – to adapt the work

- Under the following conditions:

- attribution – You must give appropriate credit, provide a link to the licence, and indicate if changes were made. You may do so in any reasonable manner, but not in any way that suggests the licensor endorses you or your use.

Captions

Items portrayed in this file

depicts

File history

Click on a date/time to view the file as it appeared at that time.

| Date/Time | Thumbnail | Dimensions | User | Comment | |

|---|---|---|---|---|---|

| current | 11:17, 26 October 2022 |  | 1,198 × 824 (622 KB) | wikimediacommons>NearEMPTiness | Cropped 53 % horizontally, 59 % vertically using CropTool with lossless mode. |

File usage

The following page uses this file:

Metadata

This file contains additional information, probably added from the digital camera or scanner used to create or digitise it.

If the file has been modified from its original state, some details may not fully reflect the modified file.

| Horizontal resolution | 236.22 dpc |

|---|---|

| Vertical resolution | 236.22 dpc |

| File change date and time | 09:14, 26 October 2022 |